Granite is a common type of intrusive, felsic, igneous rock that is granular and phaneritic in texture. It is predominantly composed of feldspar, quartz, and mica minerals, although it may also contain other minerals such as amphiboles and pyroxenes. The color of granite can vary widely, ranging from pink to gray to black, depending on the relative proportions of its constituent minerals.

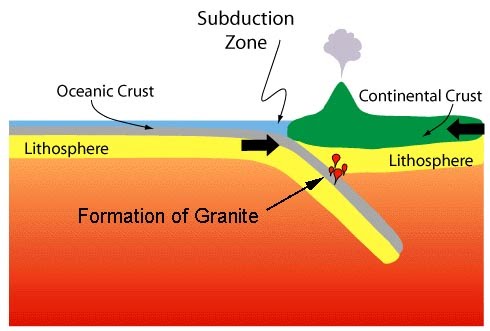

Granite forms underground through the slow cooling and solidification of magma deep within the Earth’s crust. As it cools, minerals within the magma crystallize and interlock, creating the characteristic speckled appearance and strong, durable structure of granite. This slow cooling process allows for the formation of large mineral crystals, giving granite its coarse-grained texture.

India is one of the world’s leading producers and exporters of granite. The country has vast reserves of granite deposits, with a wide range of colors, patterns, and qualities available.

Global Stonex is exporter of Indian Granite. We have our own quarry and processing unites in north and south India as well as we have tie-up with other quarries in order to provide a wide array of granite to our global customers.

Our Process of Exporting of Granite from India involves the following steps:

1. Receiving of order:

After finalisation of order after sample verification, we start mining of sourcing of raw block of granite from relevant mining area, and get the block to processing unit for further process.

2. Mining/Sourcing:

We have our own query and also tied-up with some finest quarries with well euiped modern machenaries. Raw blocks are cut from mimes using specialised cutting equipment, such as a diamond blade or a diamond wire saw.

It requires an eye of an eagle to dig up and sort natural wonders of the highest quality. Our expert team selects the most superior blocks from qurry for export purpose. Raw blocks are properly cleansed and dressed from all sides to rip off all the impuritiesmake and to make the surface of the blocks plane and defect-free.

3. Sawing the Block:

Standing still with the international quality standards, the company cuts uniformly thicker slabs as per the requirment of customer. Before cutting the block is reinforced with fibre glass net and a semi-solid reinforcement product to avoid breakage of slab during sawing.

Block is shifted and fixed on the Gangsaw trolley and taken through the slab cutting process in our

factory where have installed the most advanced gangsaw & cutters. Small size blocks are processed by simple disc saws and medium and large blocks are processed by gang saws to obtain standard 2-cm thick one-side-polished slabs.

4. Polishing the Slab:

Finely cut slabs are applied perfect blend of Epoxy Resin and is moved into the very progressive &

automated resin line and dried up at optimum temperatures. As a last facet, final glossy touch is given to our refined slabs through our automated line polishers, leaving an unparalleled and crystal glow on the slab which is 30 % more than the conventional polishing.

5. Quality check & Inspection:

We, at Global Stonex, ensure to formulate and strictly follow all the industry specific norms and quality control policies to offer international-quality products to our customers. The quality of stone product is continuously checked and assured on different parameters under the supervision of the experienced personnel at each stage from mining/sourcing, processing to packaging and container loading.

Our Natural Stones go under strict quality test based on:

– Precise Cutting

– finest Finish and edging

– Smooth Polish

– Slab size, thickness, Flatness and Right angle controlle

– Scratch Resistance

– Durability

– premium packaging

– zero breakage delivery

We also offer in-depth video calls and HD pictures of product with client at each stage of production,

packaging and loading. If a third party (such as SGS or Bureau Veritas) inspection is required, then

that is also arranged as per the requirements of the buyer.

“We aim at timely delivering the intact products in perfectly packed condition with desired quality.”

6. Packaging:

The quality of packing is as important as the quality of product for safe delivary of material. Our wooden bundles and other packing materialsare always being made by best quality Indian wood and firmly chocked / fastened. So that your stone products reach you without any hassle, breakage or scratches.

We follow the certified process & strict norms specified by IPPC (International Plant Protection Convention). Our wooden crates are always gone through Fumigation/Pesticide treatment by Methyl Bromide as per ISPM-15 International Standards in order to prevent the infection in wooden packing material.

7. Delivery:

Material is thoroughly inspected before despatch, even we welcome the customer’s appointed III party inspection, and immediately after the despatch we send the digital images, container number and other

important details to track your shipment.

In case of CIF shipment we can offer you the best possible ocean freight, we know all freight forwarders

and having good terms with them..you can even enjoy our discounted freight rates.

Some of the seliant feature of our delivary process are-

- Effective transportation and shipping system

- Timely Delivery

- Tracking of the production process at every stage

- Constant Team Connect

We do shipments on ExWork, FOB, C&F, CIF and sometimes on DDP and DDU also with payment term Telegraphic Transfer (T/T) & Letter of Credit (L/C) as per the buyers’ convineant. We can offer you the best possible ocean freight as we know all freight forwarders and having good terms with them.

Samples delivery: We can send you the stone samples free of cost, but “samples courier charges” always at buyer cost, without any exception.

8. Post-shipment Service:

By maintaining open lines of communication and offering prompt after-sales service, we strives to exceed customer expectations at every stage of the buying process. We provide complete guidance to our buyer from documentation, production to logistics. Our diligent customer care department works in coordination to ensure a hassle-free experience in the guarantee of satisfaction at

every stage. The company also offers value added assistance like providing product knowledge, customized new products and packing, marketing tools, promotional samples and continued technical support to its clients.

There is a continuous flow of information by emails to customers regarding processing of order and

arrangement of shipment and shipment trackings.